- Common John Deere 1025r Problems - April 18, 2022

A tractor is a modern machine that is beneficial to farmers with large areas of land. It is a multipurpose machine that handles various tasks like plowing, leveling, and weed controlling. Additionally, it is a time-efficient machine if you want to complete your work within a short period.

Despite all the benefits that this machine has, it occasionally experiences some problems. These problems range from engine failure to defective braking and lighting systems, among others. That should not discourage you as we will be giving sound advice on overcoming such challenges and enjoying your farming experience.

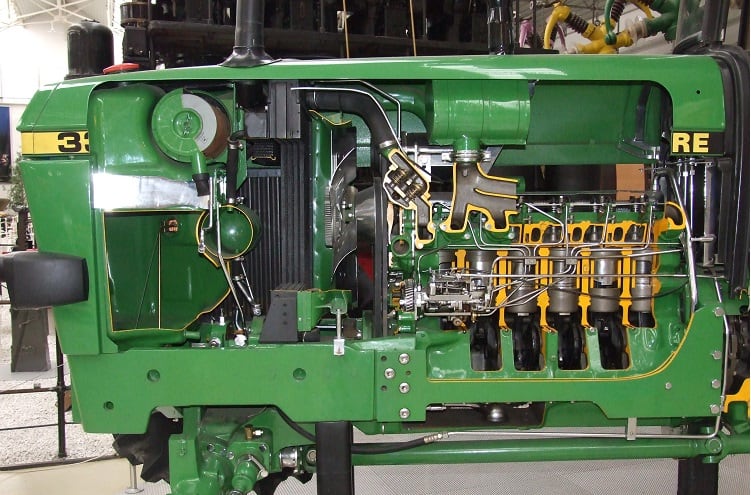

1. Engine problems

An engine is a critical component that supplies power to other moving parts. Before you decide to pay for a mechanic to repair it, why can’t you try to troubleshoot some of these problems yourself? If your engine is malfunctioning, you can begin by performing these steps:

Engine Knock

An engine knock is when an engine produces a knocking or pinging sound, which can mean several problems. A good engine allows smooth operations from the start-up to shut down.

One major cause of an engine knock could be using fuel with a low octane rating. We can describe octane rating as the ability of the fuel to prevent the mature detonation of the air-fuel mixture.

You can overcome such a problem by using gasoline with a high octane rating above what the manufacturer prescribed. Alternately, you can purchase an octane booster from any auto parts store and adjust its rating.

Another cause of engine knocking is using an incorrect or wrong spark plug. Different spark plugs have varying heat ranges hence using the wrong one prevents efficient service leading to engine knocks.

When the spark plug has an incorrect gap, it causes an engine knock. A gap is a spot where this spark plug causes ignition of the air-fuel mixture, which helps to power the tractor. A narrow gap creates a weak spark, which wide gap prevents the spark from firing at all. You can contact a professional to set the right gap to fire a spark at correct intervals.

Engine Fails to Turn Over

It is one of the biggest challenges in most engines. You may only hear a click sound as you turn the ignition key, and it stops. Here, the first diagnosis is to check the condition of your battery, which could be:

- Corroded terminals which prevent the current from traveling through

- Damaged battery cables

- The battery is dead

Begin by inspecting the cables and terminals and later test the battery. In case you lack a battery tester, then disconnect the battery and take it to an auto parts store for testing.

Engine Turns over but Fails to Start

If the engine fails to turn over without starting, then you can suspect two things. First off, check the fuel filter condition and fuel lines that run from the tank to the engine. Clogged fuel lines and filters prevent diesel from accessing its destination hence choking the engine’s supply. The only remedy is to clean or replace this fuel filter to eliminate any obstructions.

Another possible cause could be a jammed fuel control lever that lies on the engine. When it remains closed, it prevents the fuel from accessing the engine even if your fuel filter is clean. Establish the cause of a jam or consider lubricating it to get it moving again.

Engine Starts but Dies after a While

If your tractor starts but dies after a moment, then examine the fuel condition. Notably, gasoline and diesel ignite in two different ways. As for diesel, an engine will ignite under compression where the piston compresses the air-fuel mixture within the cylinder. A gasoline engine needs a spark to ignite; hence it should have good spark plugs to cause ignition.

A faulty carburetor may fail to produce the right air-fuel mixture for consistent engine operations. Over time, this component may become clogged or break down hence leading to engine failure. Perform regular cleaning to unclog it. For a broken one, replace it immediately.

Engine is Overheating

When the engine overheats, it is an indicator that there are flaws in the cooling system. Our first warning is to caution you against opening a radiator cap when an engine is hot. Such actions can pressurize the coolant and send the cap flying as it scalds you with hot steam.

Next, ensure that this radiator has a coolant in it because an empty radiator will fail you terribly. Avoid using tap water to fill the radiator as it has different minerals that can clod up and compound the problem. Use a 50/50 mixing ratio of distilled and anti-freeze water.

Use compressed air to blow off the radiator fins if they are muddy or dusty. Dirty fins prevent the radiator from lowering the temperature of the coolant well. You can call a professional if these basics fail.

2. Brake failure

Braking deficiencies are common problems in tractor management, which occur due to the braking system’s nature. Good braking is key to your safety and the public. General causes of brake failure are:

- Improper maintenance

- Tractor manufacturing defects

Most tractor brakes run on hydraulic pressure lines. One should service or replace every brake part since they have a measured lifespan. The good news is that your tractor will offer you some signals when the condition of your brake is deteriorating. Here are symptoms of defective brakes

Squeaking, Squealing, or Grinding Noises

When you begin to hear high-pitched noise that ends as you apply brakes, then it is a sign that your brake pads are faulty. Some brake pads are metallic and can produce such a sound when they contact a rotor. As you encounter such a situation, replace those brake pads before they damage your rotor, which is costly to fix.

Still, you may hear a grinding sound as you apply brakes, resulting from various things. One possibility could be a rock or gravel caught in the caliper unit. Another cause of grinding is the lack of lubrication. The brake shoe could be scraping on the brake plate due to rust. Ensure you remove any strange component in the system, such as gravel or rock.

Wobbling, Vibration, or Scraping

Vibration in the steering wheel or shaking could be due to an uneven rotor. Brake rotors happen to be big discs within the wheels. As you hit the brake pad, it hugs these rotors, thereby slowing your tractor. Ensure that all rotors are even and smooth.

An uneven rotor surface can prompt the rotor to hit one of its brake pads as it spins and causes some brake pad materials to get into the rotor on that spot. As a result, you may feel shaking when the brake pad hits such a bump in the rotor.

Another cause of rough braking is when the brake caliper is not releasing properly. The role of a brake pad is to squeeze all brake pads against brake rotors for the tractor to slow down. That piston within these caliper units is what causes the contact. Worse enough, this piston can get sticky due to wear from road debris and or heat. You can overcome this challenge by reconditioning the brake caliper.

Leaking Fluid

Whenever you encounter a soft brake pedal, allow a mechanic to look for any fluid leaking from the master cylinder. A master cylinder is a component that develops power for your brakes. When one applies brakes, such fluid pushes thin piping to create hydraulic pressure.

Suppose this fluid is leaking out of the system, it compromises power to allow these brake pads to clamp firmly onto the rotors. You can fix such a problem by emptying the brake fluid and then you remove this master cylinder. Seal the areas that you suspect a leakage and re-mount this master cylinder.

Burning Smell While Driving

When you experience a sharp chemical smell after hard braking, it is an indicator of an overheated clutch or brake. One quick remedy is to pack in a safe place and allow these brakes to cool. Failure to do that may lead to heating up of the brake fluid, which may result in brake failure.

If some come from a wheel, then it is a sign that there could be a stuck brake caliper. At this point, it could be unsafe to drive without repairs. Check the condition of these brake calipers and replace them if they are weak.

Bouncing Up and Down as You Stop

When your tractor bounces as you apply sharp brakes, the chances are that you are running on defective shock absorbers. When the tractor pulls on one side as you apply brakes, it could be a caliper or a brake problem. For instance, one caliper could be applying all the pressure during braking leading to unbalanced stopping.

You can troubleshoot this challenge by replacing it with new shock absorbers. Also, inspect the calipers and repair them if they are faulty.

3. Tire Problems

Tires ought to be in the right condition to improve your tractor’s ride and maintain safety. You must put a constant eye on your tires to ensure they are in sound condition. Here are common tire problems that you are likely to encounter:

Bald Tires

Many tractor owners encounter such challenges when tires wear out. Well, one should not expect tires to serve forever because they come from rubber materials. Two, these tires support the full weight of your tractor, that is, rolling and rocking motion as you drive it, causing baldness.

Tires should be of high quality to avoid wearing out prematurely. For whatever reason, as it happens, then replace them to prevent blowouts. Before using your tractor, perform a visual inspection by going around.

Uneven Tread Wear

Tires may not bald evenly. For example, a tire may wear on the edges and have plenty of treads further. One of the greatest contributors to uneven tire wearing is that the vehicle may be having poor alignment. Precisely, a misaligned vehicle can deteriorate the condition of brand new tires within months. For that matter, take your vehicle for alignment yearly.

Squealing When Taking Corners

It is a strange sound that makes your tractor look like it is protesting as it turns. Such a squealing sound may have three possible causes. Firstly, the machine may be having under-inflated tires, which can be easy to fix. Two, there could be worn or low tread, and lastly, misalignment at the front end.

Whenever the tractor is screaming at you, never ignore such a sound. Take corrective actions by inflating the tires if the air pressure is low. You can still inspect if there is a misalignment and align it accordingly.

Flat Spots and Choppy Wear

Choppy wear can occur on the edge of your tire as a result of bad shocks. On the other hand, flat spots on the tread can be due to packing your tractor over an extended period. It is also due to bad struts or shocks.

The only remedy is to avoid packing your tractor for weeks or months unused. Ensure that all shock absorbers are in the right condition.

Vibrations at Freeway Speeds

If tires are vibrating at normal speed, then there could be a possibility of an imbalance. Such situations require a quick fix by counterbalancing the weights.

How to Make Tires Last for Long

As a user, you should perform some of the below-mentioned maintenance practices to save the life of your tires. These tips are great in maintaining good tire condition.

Air Pressure

One can extend the life of a tire by checking and maintaining the correct pressure. Maintaining a wrong pressure may lead to sluggish handling, an increase in wear and tear, an increase in stopping distance, and heightened blowout risk.

Tire pressure can change as they lose a pound per square inch every month. Another cause is that during winter, colder temperatures may lead to low air pressure. And lastly, during summer, warm weather can increase tire pressure.

Rotate Tires for Every 5000 Miles

A two-wheel-drive tractor can experience uneven tire wear. For a four-wheel-drive one, front tires tend to wear faster than rear ones. A technician should rotate all wheels to different positions to give them a rest. Rotation is the best action to prolong life.

Check Your Alignment

When the steering vibrates, it is a sign of an alignment problem. Any smallest alignment can compromise fuel efficiency and enhance tread wear. You can take your tractor for a checkup after every six months. Don’t you know that a little maintenance can be money-saving? It also improves fuel mileage and allows you to drive safer.

4. Lightning System Challenges

Every tractor should enjoy a good lighting system to boost vision. For example, if you drive with no brake light, headlight, and lack of light indicators, it could be unsafe.

Some of the causes of lighting problems could be a bad bulb, a loose wire, a bad ground, corrosion, and a failed switch. In this section, we will be uncovering some of the lighting system challenges.

Flickering Lights

The main cause of flickering light is an electrical short or a loose wire. You can diagnose such a problem by tracing the wires in the circuit. If any of the lights flicker in the circuit, check any electrical connection for that particular light.

If all lights are flickering, inspect the common power for all lights in the circuit like a relay, switch or fuse connections. Another cause of flickering is a breaker that keeps on cycling due to a short circuit. A pure remedy is to inspect the circuit wires for any damaged insulation.

One light is Dim

A yellow or dim light may require a replacement. Other situations may be due to a challenge on the electric circuit. Start diagnosing this problem by gaining access to a socket or a light bulb you want. Remove the bulb and inspect the outer casing for chances of corrosion. Check the socket to determine if there are loose wires. In case proper voltage is accessing the socket with good ground, then replace such a light bulb.

Light Bulbs keeps Blowing Up

Such a problem may be due to an intermittent electrical short or water presence in an assembly. Inspect this assembly to establish if there is any water in it. You can perform a quick and minor repair by drilling a small hole to cause water to drain out. Another option is to replace this assembly.

Turn signals don’t work

One of the key reasons why such happens is a burned-out bulb. You can solve this by reaching out to the bulb that does not work and inspecting it. Usually, any burned bulb has a dark side on the glass. Similarly, check the socket for proper voltage. If the voltage is in the right parameters, you can perform a bulb light replacement.

Maintenance Tips for Headlights

Headlights are critical for illuminating during night driving, while braking lights signal to other road users when you are slowing down or stopping. Whenever you are operating your tractor, ensure that these two lights are in working order by observing the following:

Inspect the Lights

Frequent inspections of brakes and headlights ensure that they remain in proper condition. It is a quick walkthrough to examine these lights for any failures, dimness, and other defects. While checking brake lights, you need a colleague to assist you as you step on brake pedals. Take action as appropriate whenever you find that one or more components are out of order.

Replace Defective or Broken Parts

One should replace any damaged or broken headlight that no longer functions properly. Driving with a broken brake light or headlight light may put you on the wrong side of the law. If you get yourself in a similar condition, access an auto repair shop for correction before proceeding with your journey.

Clean and Polish your light

Keep your brake lights and headlights clean and free from debris. If they have clouds of dust or mud, it becomes a serious issue to your visibility. Give them a thorough cleaning to produce dependable light during a night drive.

Avoid changing just one light

When your vehicle demands changing lights, avoid doing it singularly. Such actions maintain light consistency. If bulbs have mismatched light intensity, it can be a nightmare to drive at night. You should not risk allowing one light to be dimmer than its counterpart.

5. Suspension System Issues

The suspension system is essential in smoothing out the ride and keeping your tractor in control. Precisely, it provides comfort to the driver by reducing the impact on several bumps. The suspension system includes different components such as chassis, shock absorbers, and spring coils that support the tractor’s weight. Struts and anti-sway bars are part of the suspension system.

Struts are ideal in offering structural support the tractor needs and create a stable body and frame. The role of an anti-sway bar is shifting the wheels and keeping the tractor stable while turning around corners. Some common suspension problems are listed below:

Feeling Every Bump

One of the key roles of suspension is to provide comfort by smoothing out bumps. Whenever you feel every bump, then it is a sign that your struts or shock absorbers are faulty. If the tractor has shock absorbers, inspect them for any possible leaks that could dampen the bouncing. If the tractor has struts, listen to any knocking sound as you drive over bumps. Check the condition of these struts and replace them if they are defective.

One Corner Sits Low

If you notice that one corner of your tractor sits low, there are chances of damaged or worn out spring. As a result, you might encounter a clunking noise when you drive over bumps or any deep pothole.

You can overcome the above problem by ensuring that all tires are correctly and equally inflated. You can still contact the mechanic to check your suspension if you notice a creaking or squealing sound.

Difficulty When Steering

When the steering becomes difficult as you drive at a low pace, it is a perfect indicator that there is a steering system or suspension challenge. Furthermore, it could be a leaking power steering rack or a faulty pump steering pump. When your steering is not in good condition, it is wise that you seek mechanic’s services.

Oily Shock Absorbers

If you observe that the shock absorber is getting oily, then there is leaking liquid fluid. Consequently, such means that they will fail to work optimally. As the best practice, inspect your suspension system regularly and get it fixed by the mechanic as soon as you notice a fault.

6. Transmission Problems

Your tractor’s transmission system uses engine power to spin the wheels and keep your engine within particular revolutions per minute. The arrangement of the transmission system depends upon the type of drive, whether two or four-wheel drive. Major transmission problems require inspection, dissembling, cleaning, and rebuilding. Parts of a transmission system include:

- Clutch

- Gearbox

- Propeller shaft

- Differential

- Live Axle

Here are symptoms of a faulty transmission system:

Weird Smells

Pay proper attention if you sense a burning smell from your engine. When transmission fluid degrades or runs low, it overheats and begins to burn. As a result, it causes your engine to run hot, contributing to excess wear and corrosion. Other causes of burning smell are trapped plastic or dripping antifreeze. Always check out to arrest the problem of replacing this transmission fluid.

Strange Sounds

If your tractor experiences humming, clunking, or whining sounds, there could be a problem in the automatic transmission system. Additionally, a faulty manual transmission could give loud like machine sound too. Another sign of a weak transmission system is encountering a clunking noise as you shift gears. Take your tractor to a mechanic for inspection and repair.

Fluid Leak

Your tractor has six main fluids that cool, lubricate, brake, and help you steer or clear the windscreen. If the fluids break down or leak and fail to replace them fast enough, they could compound the engine’s problem. You can detect an automatic fuel leak by its sweet smell or red color. You can still detect a toasty smell or observe a darker color when it is beyond its prime. Inspect for fuel leaks if you realize suspicious fluids on the driveway.

Alternatively, warm the engine by performing a short drive and check the transmission fuel level with a dipstick. If the level is low, then it means there is a leakage. Reseal it and top it up.

Noisiness

Excess noise is a sign of problems. For example, if you operate your car in neutral and experience a noisy bumping sound, go for an engine check. The solution could be low fluid or wrong fluid used hence causing such flaws. Another possibility could be bearing or gear teeth, which need replacements.

Red Engine Light

Always check for a red engine light because it is a signal that something is not measuring up in the system. The modern vehicle has sensors that can relay a warning signal to you in all systems transmission inclusive.

For example, a minor thing as a loose gas cap can trigger the problem. Perform a simple diagnostic scan to determine the cause before matters get out of hand.

Slipping Gears

Any tractor will rely on an external input to cause gear changes. For an automatic transmission, the driver can choose a reverse, neutral, or drive. It can be dangerous for you if your car has slipping gears. Worn out transmission fluids bands and low fluids can still cause gear slipping. The only remedy is to align these gears so that they clamp well as you shift them.

Common Tractor Problems by Make & Model

As we continue to build out this site, follow along with our latest model specific troubleshooting & fix guides:

FAQs

Question: What are the different types of lights in a tractor?

Answer: A tractor has multiple lights, each with a specific function. First off, some headlights enable the driver to see well in the dark. Taillights are always at the rear to help other drivers recognize that there is a vehicle ahead. Brake lights are also at the rear, which signals that you are slowing down or stopping.

Question: How can I brake properly?

Answer: The rules are simple. Avoid jabbing your brake by applying slowly and smoothly to pressure it. When you succeed, stop or slow down, begin to ease your foot from the brake lever easily. Avoid releasing the brake suddenly to ensure the process is even.

Question: How can I diagnose engine problems?

Answer: Inspect the piston rings and determine if they are faulty. You can also check the condition of both intake and exhaust valves to ensure that they have proper sealing. In case it lacks a spark, your engine may fail to start. Replace it to get better results.

Question: What happens if the suspension system in a tractor is bad?

Answer: Driving a tractor with a damaged or broken suspension is like running with a broken leg. It causes the tractor to remain unstable and unbalanced, which is a tricky scenario that can lead the driver to lose control. Over time, if the conditions remain unchecked, it may lead to breaking or tearing out parts.

Bottom line

You must maintain your tractor if you desire to get a long service. Remain observant by responding to slight signs before they develop into large measures and cost you dearly. Your success depends upon following our tips in this write-up.

Finally, you can afford a smile if you realize your tractor is serving you for a long time without becoming unrepairable.

A mechanically sound machine will offer great benefits and improve your production if you use it for different agricultural purposes. Take up the responsibility and keep your tractor in sound condition to complement its purpose in your life.